All Types of Non-Metal Cutting

- Home

- Engineering Works

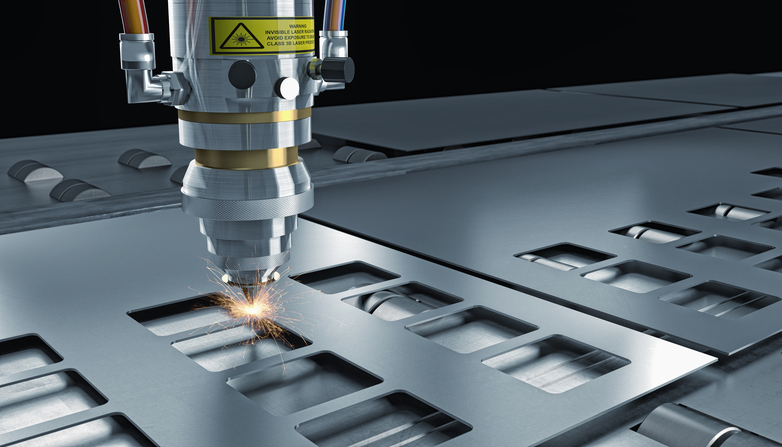

- Laser Cutting

- All Types of Non-Metal Cutting

Engineering Works

All Types of Non-Metal Cutting

Plastics

Using lasers to cut plastic achieves precise, fast and repeatable cuts in many types of polymers. Compared to traditional cutting methods, laser systems offer many advantages like precise laser control, high accuracy and speed. Others include: Non-contact cuts.

Precise, fast and repeatable cuts in many types of polymers laser systems offer many advantages like:

- Precise laser control

- High accuracy and speed

- Lasers eliminate cleaning, sharpening and replacing cutting blades

- Focused, localized laser energy creates very narrow cuts

- Switch between patterns without changing parts

Glass

Glass cutting by conventional mechanical methods, such as diamond scribing and breaking, have considerable disadvantages because of the accuracy and the limited scribing quality (micro-cracks, chipping). Principally, a whole series of additional time-consuming post-processing steps such as grinding, polishing and etching are necessary in order to remedy the damage which the mechanical processes has left behind and to ensure the required contour accuracy.

If the laser is used for glass cutting, such disadvantages can be avoided. Contact-free laser processes enable the production of thinner glass layers and new material compositions. Depending on the glass composition and requirements, there are different lasers for glass cutting.

Ceramics

Lasers can cut many types of ceramic materials. The most common is alumina silicate which requires full ablation or the scribe-and-break technique. Each has its own advantages depending on your application’s requirements. Unlike other methods, ceramic laser cutting achieves precise heat control to cut detailed patterns.

Advantages include:

- No contact

- Precise control

- No consumables

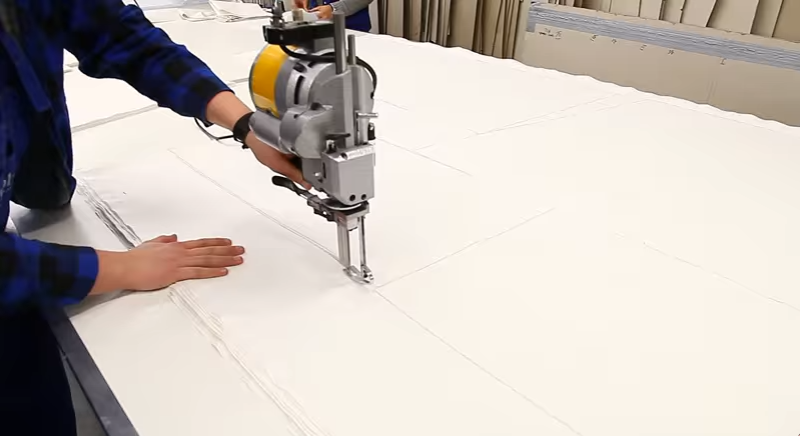

Fabrics

As well as for wood, leather or homogeneous and fiber-reinforced plastics, the method of laser sublimation cutting is preferably used for fabrics. A great advantage is the melting of textile fibers by the thermal separation process, so that fraying of the fibers as in the mechanical separation process can no longer occur.

Above advantage is also utilized in the separation of airbag fabrics and clothing fabrics. Above all, multi-layer materials are cut with higher performance.

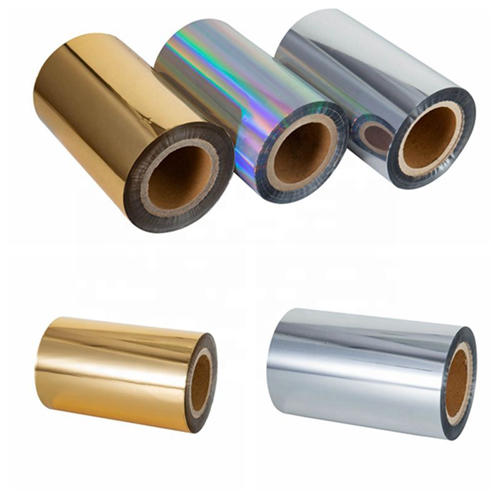

Foils, labels and self adhesive substrates

With the laser technology, clean and precise cuts can be achieved in the cutting of foils and labels. There is no post-processing required and flaking of the material as in the punching process – thanks to contactless and force-free processing.

Only the first layer of the material is cut while the second layer remains intact under it during the "kiss cutting" process. This cutting method is mostly applied in self-adhesive materials and is a frequently used process in the production of stickers.

Wooden

The Wood Laser Cutting Services provided by us are highly acclaimed for their timely and efficient provision.

Birch, maple, cherry, mahogany, walnut, and oak are beautiful materials to work with and are favorites for customers.

In Wooden cutting there are two types of plywood that are good for laser cutting are birch and bamboo laser plywood. Like maple and cherry, birch is a dense but easy-to-use hardwood that's readily available. It's great for beginners looking to get into laser cutting because it cuts smoothly and reliably.